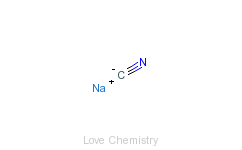

Sodium Cyanide

Product Name: Sodium Cyanide CAS No.:143-33-9

Chemical Formula: NaCN Molecular Weight:49.01

Melting Point: 563.7 °C Boiling Point.:1496°C

EINECS No.: 205-599-4

Product use

Sodium cyanide is an important basic chemical raw material, which is used in basic chemical synthesis, electroplating, metallurgy, organic synthesis, medicine, pesticide and metal treatment. Complexing agent, masking agent. Gold and silver and other precious metals extraction and electroplating.

It is used as quenchant for various steels in mechanical industry.

As the main components of copper, silver, cadmium and zinc in electroplating industry. In the electroplating solution, the anodic polarization can be reduced, the normal dissolution of the anode can be ensured, the bath can be stabilized, and the cathodic polarization can be improved to obtain a uniform coating.

It is used to extract gold, silver and other precious metals in metallurgical industry.

In the chemical industry, it is the raw material for the production of various inorganic cyanide and hydrocyanic acid. It is also used for the production of polymerized organic glass, various synthetic materials, nitrile butadiene rubber and synthetic fiber.

In dye industry, it is used to produce cyanuric chloride (intermediate of reactive dye and raw material of whitening agent)[ 2]

In pharmaceutical industry, it is used to manufacture methyl cyanoacetate and diethyl malonate. In textile industry, it is used as mordant, liquid carburizing and nitriding of steel.

The main inorganic cyanide produced directly from sodium cyanide are sodium xanthate, potassium xanthate, potassium cyanide, zinc cyanide, barium cyanide, cuprous cyanide, sodium thiocyanate and potassium thiocyanate; Organic cyanides include cyanoacetic acid, malononitrile, methionine, cyanobenzyl, cyanuric chloride, etc. The main products of hydrogen cyanide produced by sodium cyanide are: methyl methacrylate, butyl methacrylate, methacrylic acid, azodiisobutyronitrile, azodiisobutyronitrile, iminotriacetic acid, hydroxyacetonitrile, etc.

Storage Condition

Packing method: put it into plastic bag, seal the mouth of the bag, and then put it into a strong steel drum with a thickness of not less than 0.75mm, tightly clamp the lid, and the net weight of each drum is 50kg; Screw mouth glass bottle, iron cap pressure mouth glass bottle, plastic bottle or ordinary wooden case outside metal barrel (can); However, plastic bags should be added outside the glass bottles.

Precautions for transportation: during railway transportation, the dangerous goods shall be loaded in strict accordance with the dangerous goods loading table in the regulations for transport of dangerous goods issued by the Ministry of railways. Before transportation, it is necessary to check whether the packaging container is complete and sealed. During transportation, it is necessary to ensure that the container does not leak, collapse, fall or damage. It is strictly forbidden to mix with acids, oxidants, food and food additives. During transportation, transport vehicles shall be equipped with leakage emergency treatment equipment. During transportation, it should be protected from sunlight, rain and high temperature. Road transportation should be carried out according to the prescribed route, and it is forbidden to stay in residential areas and densely populated areas.

Prev:No